浏览:次

Dr. Dou Xiaofeng, Associate Professor Liu Zhichao and others from our laboratory published an article entitled 3D DEM modeling on mechanical weakening of gas hydrate-bearing sandy sediments during hydrate dissociation in the journal Computers and Geotechnics.

1、Abstract

The dissociation of natural gas hydrates (NGHs) during production weakens the mechanical properties of hydrate-bearing sediments (HBSs). Understanding and predicting the mechanical behaviors of HBSs is crucial for the safe development of NGH reservoirs. This study presents a novel approach based on the discrete element method (DEM) to describe the mechanical weakening of cementing-type gas hydrate-bearing sandy sediments (GHBSSs). Hydrate dissociation is simulated by reducing the parallel-bond radius based on a specific damage evolution law. The Weibull statistical distribution is incorporated into the model to characterize the heterogeneity of hydrates in GHBSSs. Subsequently, a series of numerical triaxial compression tests are conducted to investigate the mechanical weakening behavior of cementing-type GHBSSs and the mechanical effect of the heterogeneous distribution of hydrates.

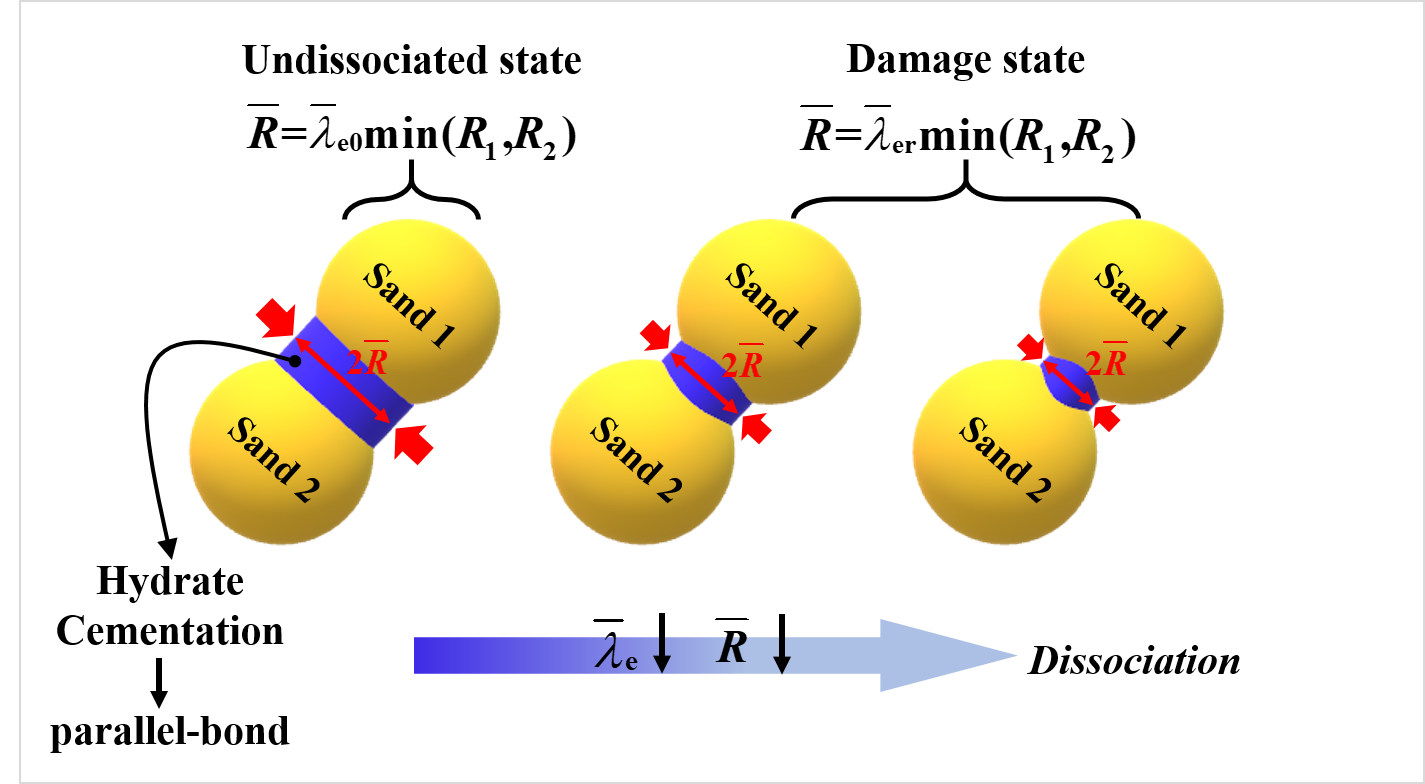

Fig. 1. Schematic representation of the damage caused by the gradual decomposition of hydrate

between sand particles by reducing the hydrate cementation radius

2、Methods

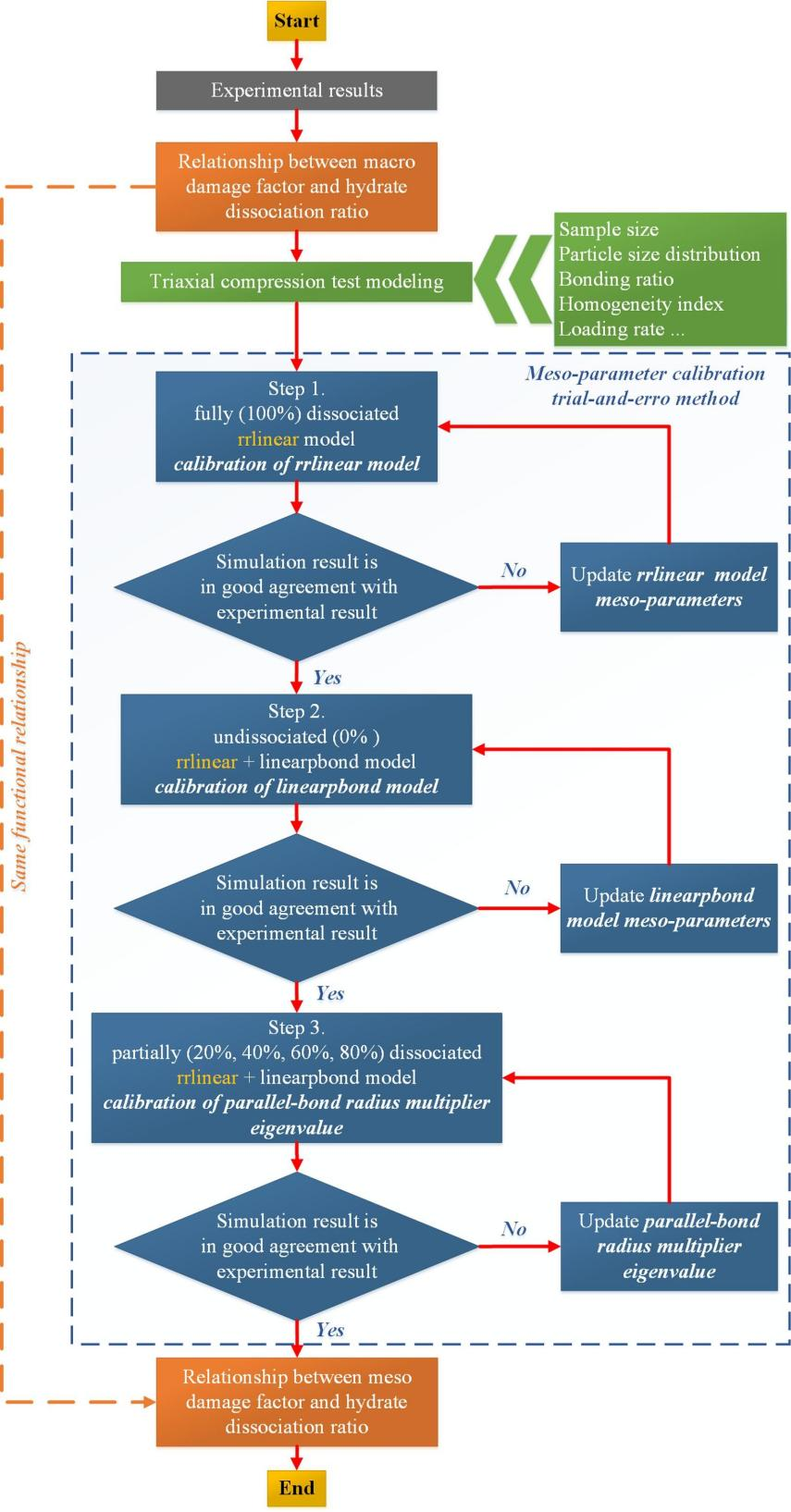

In this study, the commercial software PFC3D (version 6.0) was used for three-dimensional modeling, the rrlinear model was used for interparticle contact, and the linearpbond model was used for part of the interparticle contact to characterize the cementation of hydrates. The Weibull statistical distribution is introduced into the model to characterize the heterogeneity of hydrate in hydrate-bearing sandy sediments. Macroscopic damage is caused by the accumulation of mesoscopic damage, and the function of macroscopic damage factor and hydrate decomposition rate is constructed according to the indoor triaxial compression strength under different hydrate decomposition rates. Assuming that the mesoscopic damage obeys the same functional form, the eigenvalue of the parallel cementation radius multiplier is selected as the variable of the mesoscopic damage factor function, and the mesoscopic parameter calibration is carried out by combining the numerical triaxial compression test and the trial and error method, and the mesoscopic damage factor is established The relationship between hydrate decomposition rate and hydrate decomposition rate is used to characterize the mechanical degradation behavior caused by hydrate decomposition.

Fig. 2. Process for establishing the relationship between the meso damage factor and hydrate dissociation ratio

3、Simulation results

(1)Stress - strain response and bond breakage development

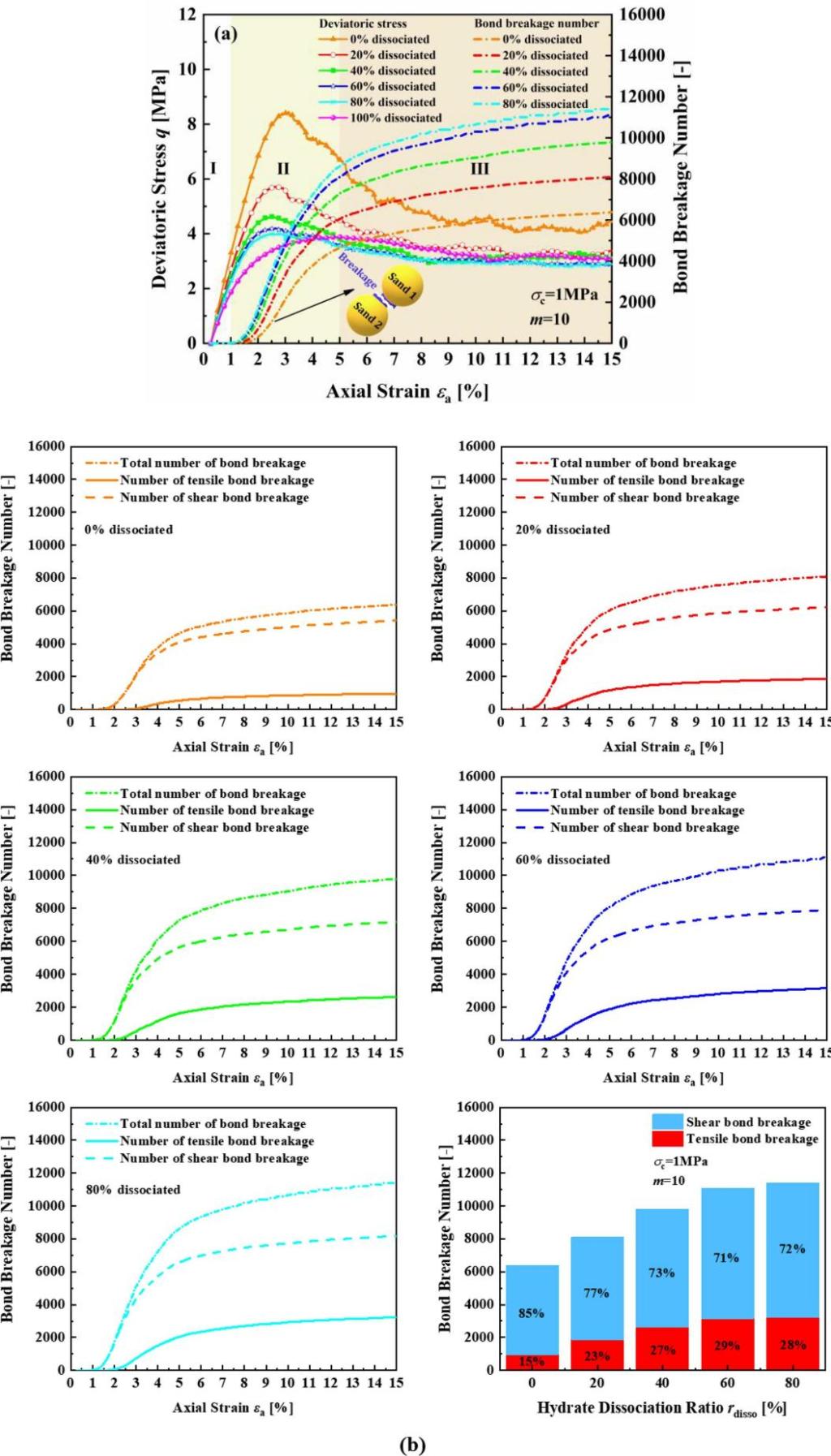

Fig. 3a shows the evolution of the deviatoric stress q and bond breakage number for different rdisso values in the numerical simulation. In general, the peak q of the GHBSSs decreases as rdisso increases, whereas the number of bond breakages in the GHBSSs under the same strain condition increases with rdisso. The hydrate dissociation weakens the bearing capacity of hydrate cementation between skeleton particles resulting in the phenomenon above.

Fig. 3. (a) Evolution of deviatoric stress and bond breakage number with different

hydrate dissociation ratios in the numerical simulations

(b) Comparison of the total bond breakage number, shear bond breakage number and tensile bond

breakage number with different hydrate dissociation ratios

(2)Deformation characteristics

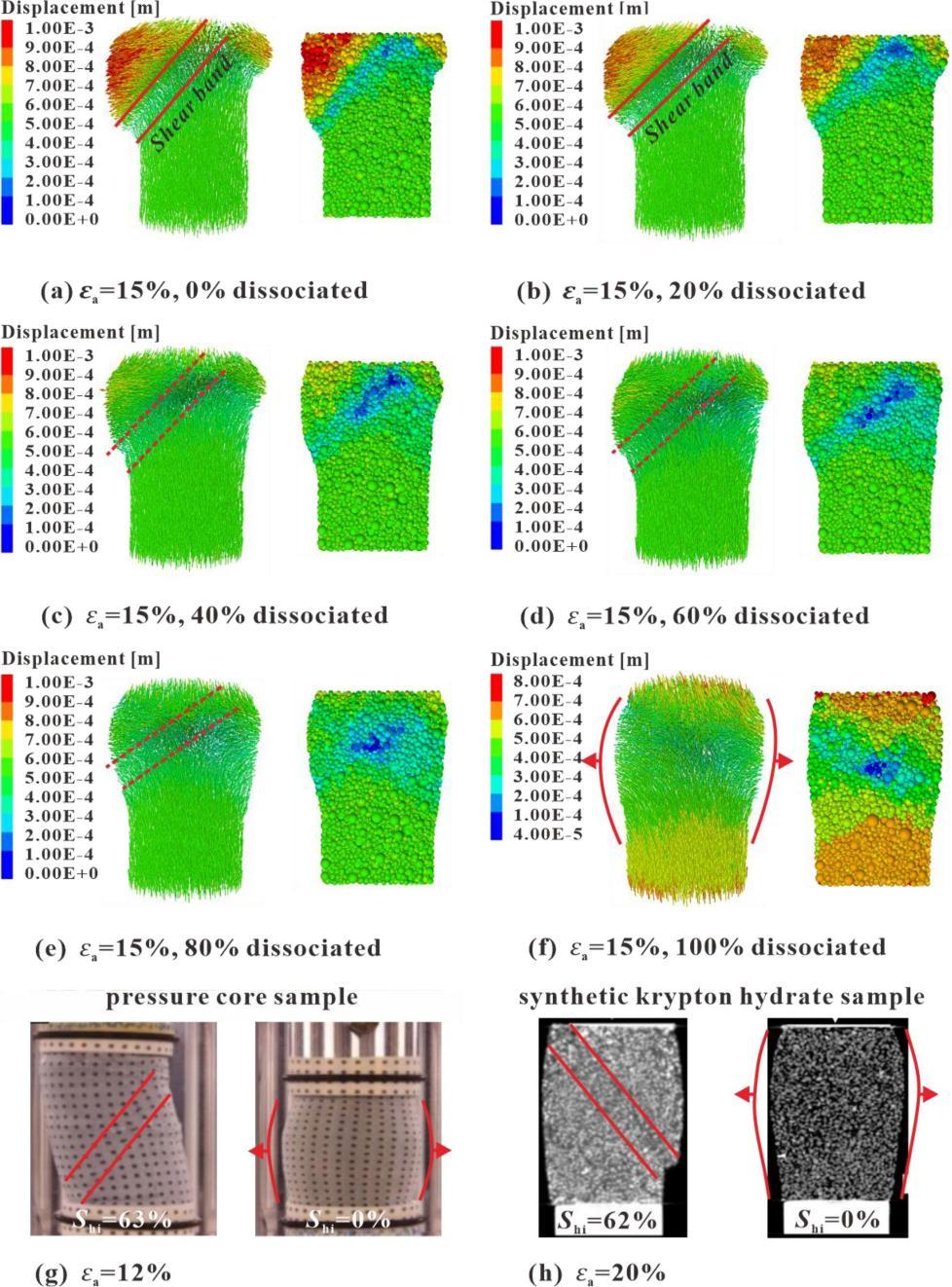

A comparison of the final triaxial compression deformation patterns of initially, partially and fully dissociated GHBSSs is shown in Fig. 4. As shown, as rdisso increases, the shear bands mentioned above are no longer obvious (Figs. 4a - e). For the fully dissociated GHBSSs (Fig. 4f), the deformation pattern shows radial spherical expansion, which differs significantly from the deformation patterns of other dissociated cases. These results indicate that the hydrates contribute significantly to the mechanical deformation of GHBSSs and that the deformation pattern of the GHBSSs changes from brittle to ductile as rdisso increases from 0 % to 100 %.

Fig. 4. Comparison of final triaxial compression deformation patterns. (a) Initially, (b)-(e) partially, and

(f) fully dissociated GHBSSs from the simulation (in each subfigure, the particle displacement vector is

represented by arrows on the left, and the longitudinal section of the particle displacement field is on the right).

(g) Pressure core samples with and without NGHs (Yoneda et al., 2015) and

(h) synthetic samples with and without krypton hydrates (Yoneda et al., 2016) in the experiment.

(3)Effect of heterogeneity on mechanical strength and modulus

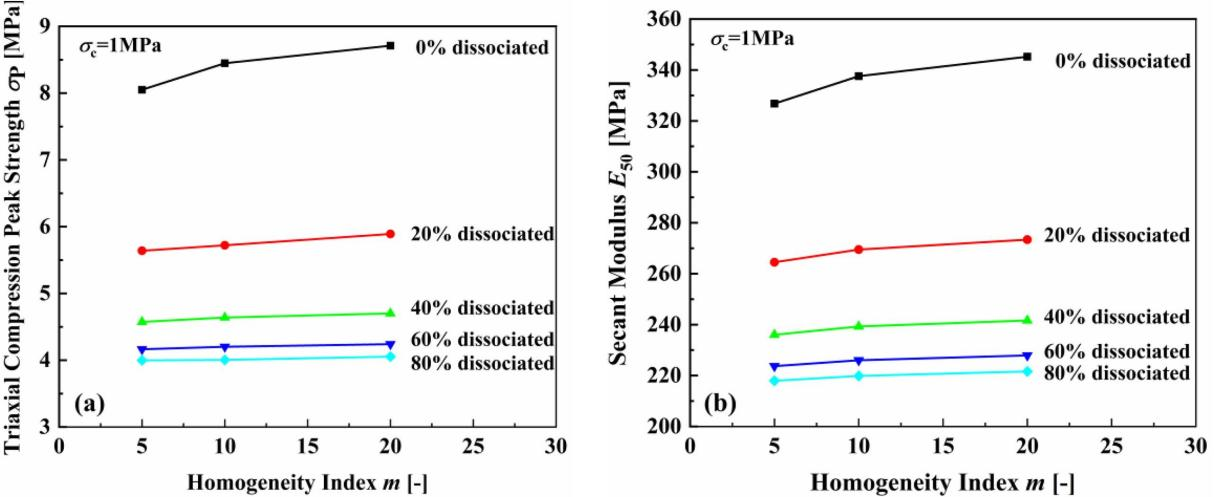

The σp and E50 of GHBSSs with different m (5, 10 and 20) under different rdisso (0 %, 20 %, 40 %, 60 %, and 80 %) are plotted and compared in Figs. 5a and 5b, respectively. In general, σp and E50 increase with m under the same rdisso. Moreover, as rdisso increases, the amount of hydrates decreases, and the contribution of the strength and stiffness of hydrates to the overall strength and stiffness of the GHBSSs is no longer significant; therefore, the difference between the σp and E50 of the GHBSSs with different m becomes increasingly smaller. In other words, the sensitivity of σp and E50 to m decreases as rdisso increases.

Fig. 5. Comparison of (a) triaxial compression peak strength and

(b) secant modulus for different homogeneity indices under different hydrate dissociation ratios

(4)Relationship among mechanical strength, initial hydrate saturation and dissociation ratio

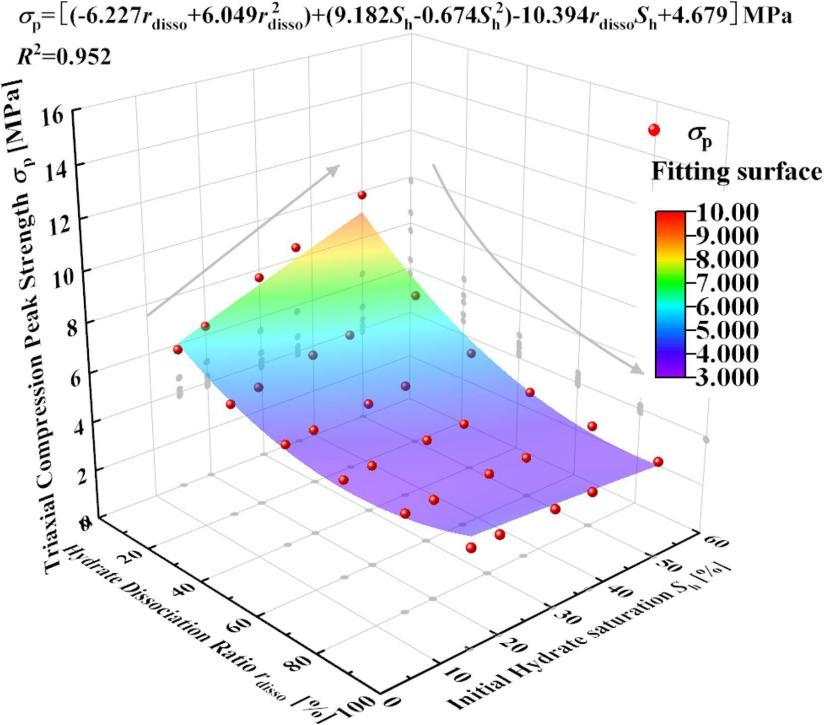

The triaxial mechanical behaviors of GHBSSs with Sh (15 %, 20 %, 30 %, 37 %, and 50 %) under different rdisso values (0 %, 20 %, 40 %, 60 %, 80 %, and 100 %) at σc = 1 MPa and m = 10 were systematically simulated, as shown in Fig. 6. It can be observed that the higher Sh is, the higher σp of the GHBSSs at the same rdisso. The relationship among σp, Sh , and rdisso can be described by the fitting equation shown in the equation below, and the R2 is 0.952.

Fig. 6. Fitting surface of the triaxial compression peak strength under different initial hydrate saturations and

hydrate dissociation ratios at σc = 1 MPa and m = 10 (the red dots are the simulation results,

and the gray dots are the projections of the red dots on each plane).

4、Conclusions and perspectives

(1)The DEM model successfully captures the weakening behavior of the mechanical properties of cementing-type GHBSSs during hydrate dissociation, which is consistent with the experimental results.

(2)Bond breakage development in cementing-type GHBSSs under triaxial compression can be categorized into three stages: initially developed, rapidly developed, and stabilized. As the hydrate dissociation ratio increases, the bond breakages develop significantly, and the strength of the cementing-type GHBSSs decreases.

(3)As the hydrate dissociation ratio increases from 0 % to 100 %, the deformation pattern of the cementing-type GHBSSs changes from brittle to ductile, and the characteristics of the shear band are no longer obvious; additionally, the distribution of bond breakages and rotating particles changes from being concentrated in the shear band to dispersed inside and outside the shear band, and the maximum dilatancy angle decreases linearly.

(4)The triaxial compression peak strength and secant modulus of the cementing-type GHBSSs increase with the increase in the homogeneity index under the same hydrate dissociation ratio, but the sensitivity of the triaxial compression peak strength and the secant modulus to the homogeneity index decreases as the hydrate dissociation ratio increases.

(5)A fitting equation describing the relationship among the triaxial compression peak strength, initial hydrate saturation, and hydrate dissociation ratio is obtained based on high volumes of simulation data. This allows the mechanical properties of the GHBSSs to be predicted in the absence of experimental data.

Article Source: https://doi.org/10.1016/j.compgeo.2022.105116